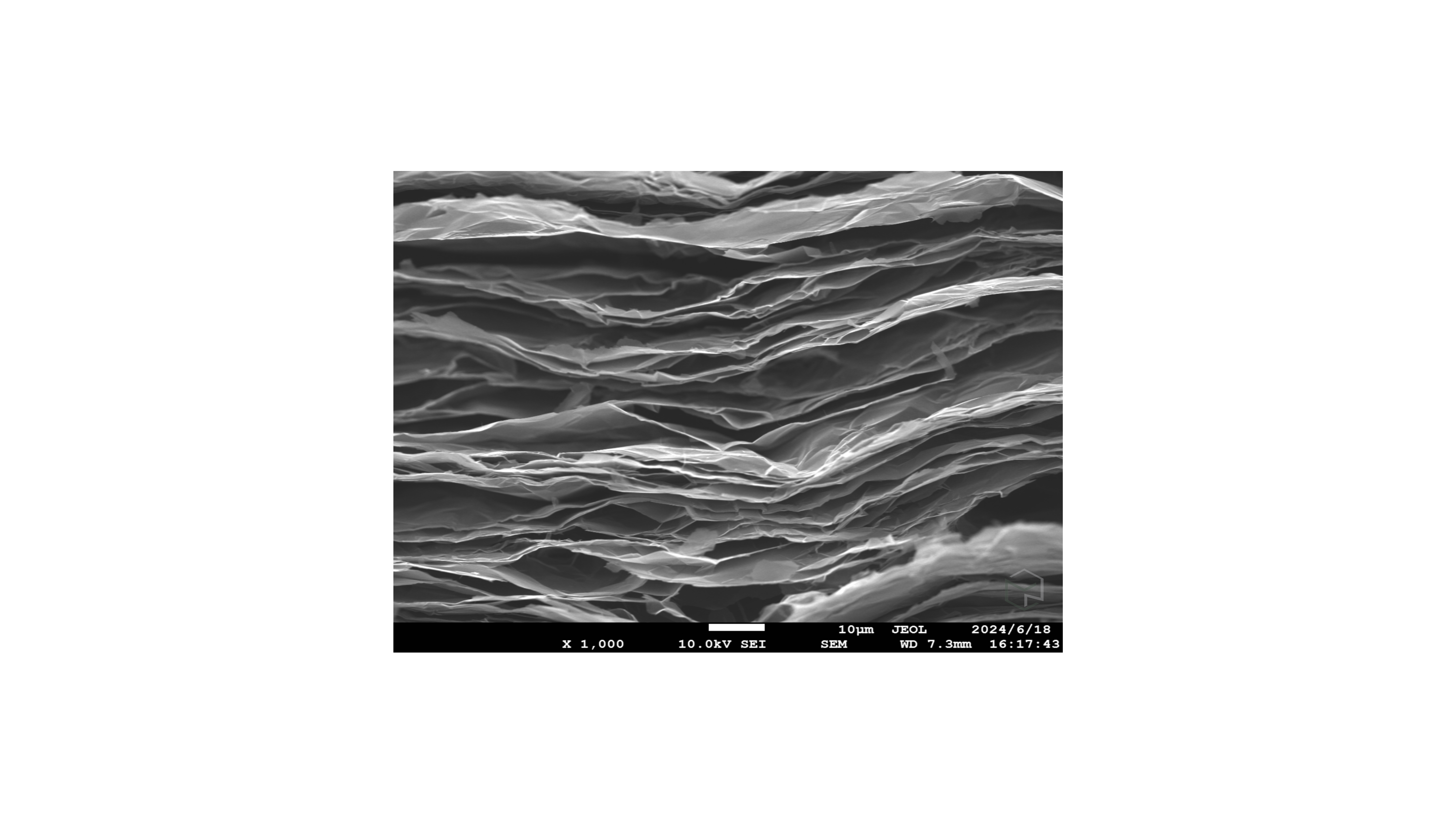

1. High thermal conductivity, with a horizontal thermal conductivity of up to 1650 W/m·K;

2. Soft and foldable, with a folding endurance (R2, 180°) of more than 400,000 cycles, and nearly no performance degradation at the folded areas.

Flexible thermal conductive film is a product with excellent properties such as high thermal conductivity, high electrical conductivity, high flexibility, and lightweight. By adjusting the micro self-assembly morphology of the membrane material, the flexibility of the membrane material is improved, which is very suitable for the heat dissipation needs of the shaft structure.

Guangdong Public Security Registration No.44190002005690

Guangdong Public Security Registration No.44190002005690