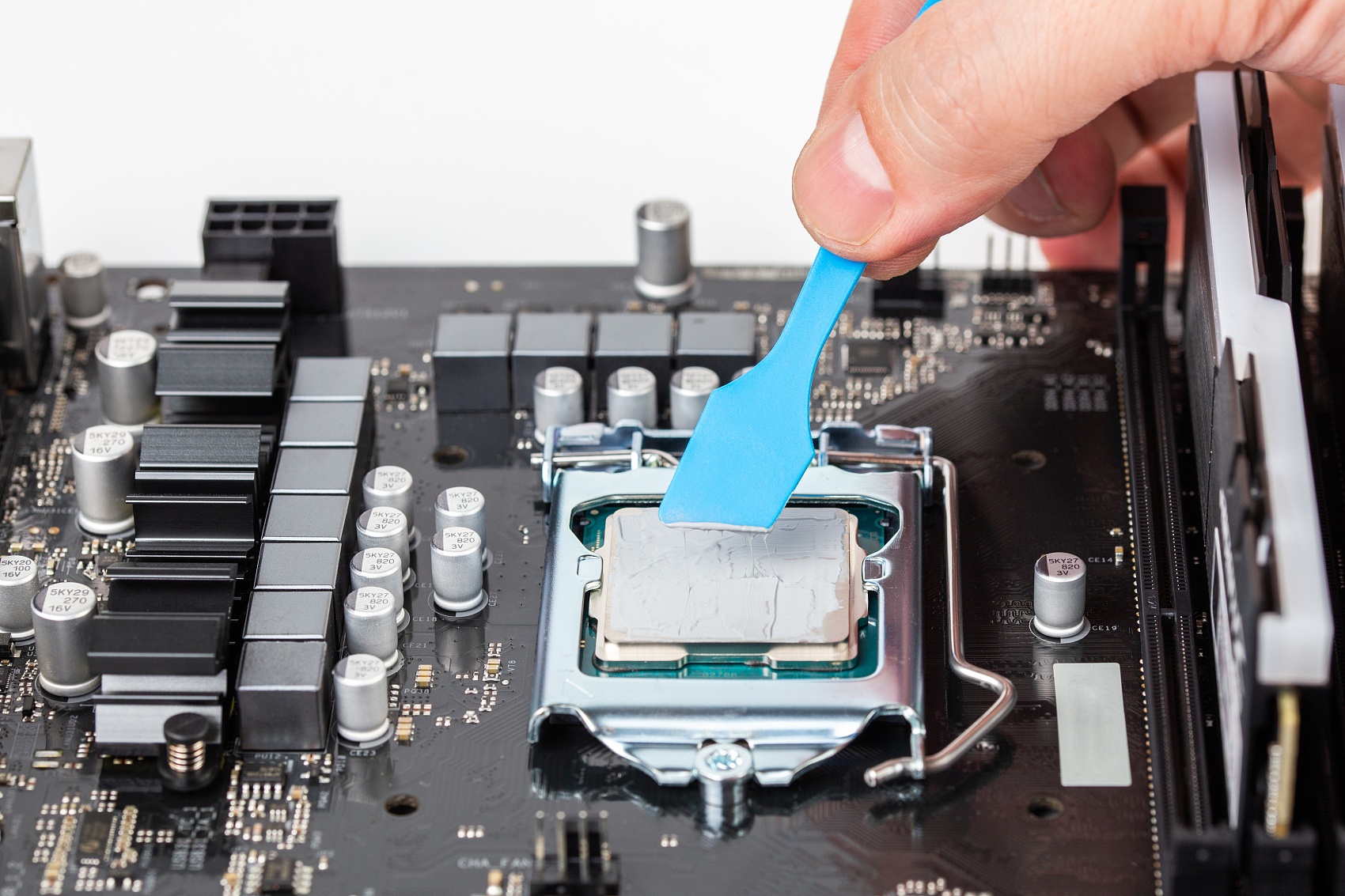

1. Thermal conductivity is stable and reliable, with low thermal resistance;

2. Great thermal endurance, operates under -40-200℃ steadily

3. Non-toxic, odorless, non-corrosive, and environmentally friendly.

Thermal interface materials are crucial components widely used in heat dissipation systems for cooling and protecting integrated circuit chips. Morion Nanotech, leveraging its deep understanding of graphene materials and thermal fillers, has developed reliable and highly cost-effective graphene composite thermal grease to meet the stringent requirements of the electronics industry, effectively addressing challenging heat dissipation issues. This material is an ideal thermal interface solution for electronic components.

Guangdong Public Security Registration No.44190002005690

Guangdong Public Security Registration No.44190002005690